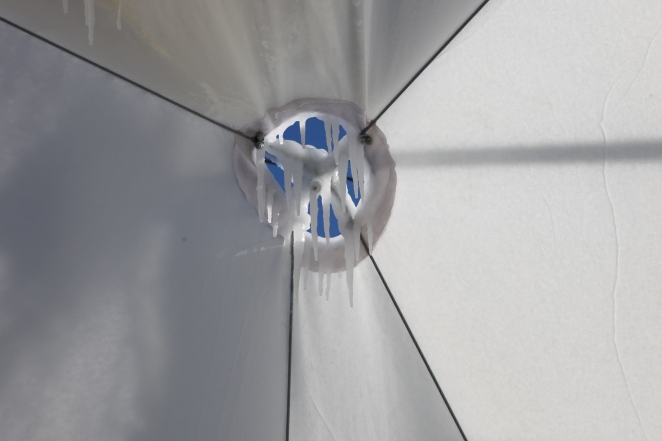

During a particularly cold week in mid February (-20C to -30C) we were able to carry out the structural load test we had been hoping to conduct for this project. The aim was to create a sheet of ice on the outer surface of the fabric and to release the cables to see if the folded geometry would support the loads of the ice and snow.

Over the course of two nights during that week we applied 28 coats of water and were successful in creating an ice sheet with a varying thickness of ¼” – ½”. On the morning of the third day we arranged to loosen the turnbuckles and slowly release the tension support of the upper cables, thereby releasing the support of the connecting “grab cables” that was pulling the fabric and interior cables into form. Despite enormous cracking sounds and popping that was coming from the shattering ice that had adhered to the steel cables from the spray operation, the form of the fabric and ice shell did not budge. Once fully released from the supports of the cables, it was clear that the building had not moved and it was fully supporting itself; Fabrigami was officially a free-spanning fabric reinforced ice shell structure spanning 28’ (wide) x 38’ (long) x 12’ (tall)!